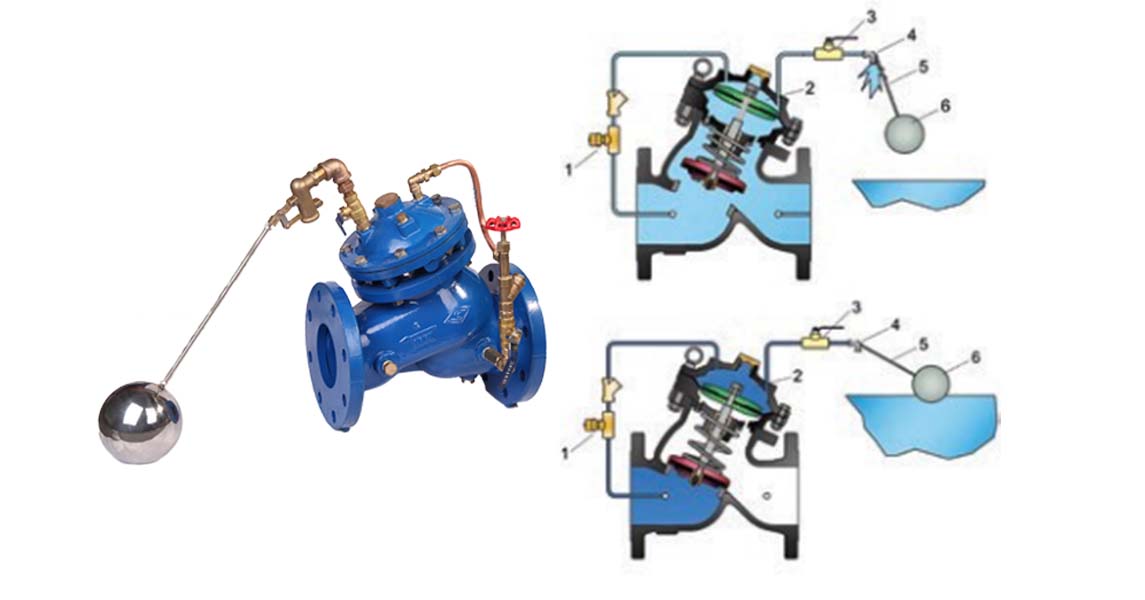

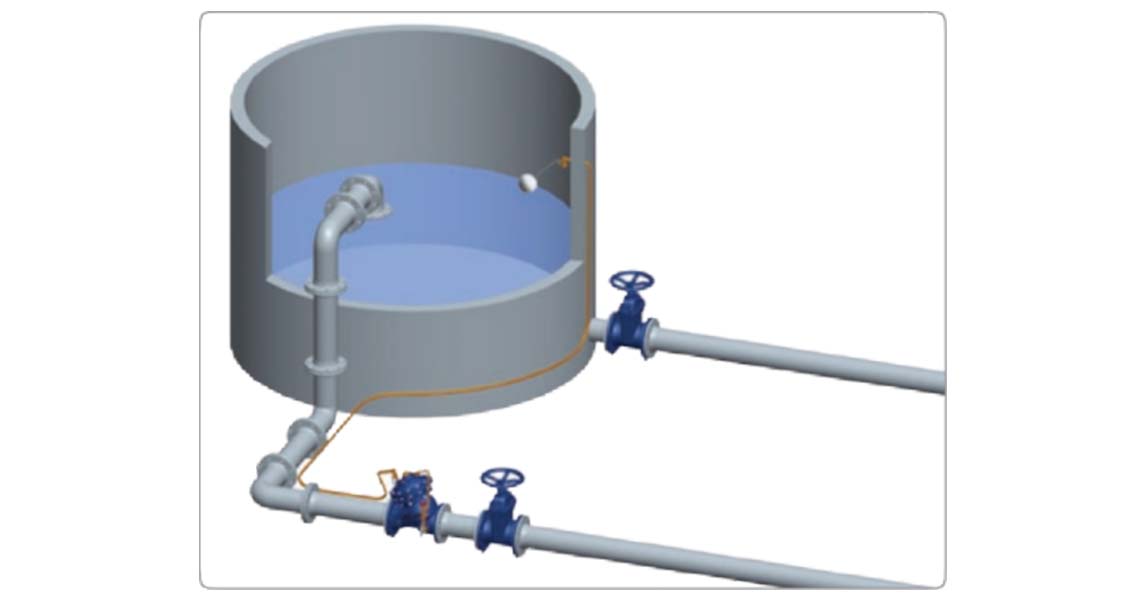

SK750X Remote Float Control Valve is a diaphragm type of hydraulic control valve driven by the hydraulic pressure within the piping system, designed with adjustable parallel float. The valve is capable to maintain the water surface at set position despite the fluctuation of flow rate and widely applied where there is water reservoir or water box for injection of water.

◔Operational principle

SK750X Remote Float Control Valve is controlled by angle valve, float and ball lever, and equipped with needle valve, mini strainer and ball valve, etc.

Under normal conditions, water flow comes continuously from the inlet opening to the upper cavity room

(2) of the basic valve through the needle valve (1); When the float is not reaching the set position, the angle valve 4 remains open. The water that enters the upper cavity room of the basic valve discharges into the water tank and no accumulation within. Under this condition, the disc of the basic valve remains open at the water pressure from the inlet opening to allow water supply to the water tank. With the raising of the water surface, the float (6) gradually raises and closes the angle valve (4). Pressure gets accumulated within the upper cavity room and drives the membrane down to close disc and the basic valve gradually. When the water surface reaches the set position, the angle valve close completely and so with the basic valve and the water supply stops. When water position declines, the pressure within the upper cavity room gets released through the angle valve and the basic valve opens to continue with water supply.

Needle valve (1) serves to control the closing speed of the valve to prevent formation of water hammer; In case the float is not working, ball valve (3) can close the basic valve for emergency cut-off.

◔ Property and advantages

• Driven by pressure of pipe system, work automatically with energy of pipe system to achieve energy conservation and environment protection.

• Controlled by the pilot valve, lower energy consumption, achieve accurate pressure reducing results, have function of stabilizing pressure after the valve.

• Dual cavity design, with functions of fully opening and fully closing. Slow shut causes no pressure fluctuation, and the diaphragm with support is well protected.

• Have internal orifice, connect bottom cavity and outlet of the basic valve, make sure stability of reaction to keep stability of pressure after the valve, avoid any vibration and noise.

• Channel with straight-flow, slight friction loss, no eddy flow and turbulent flow, cut down the damage of cavitation.

• Long pitch orientation design for stem move, stable and no gap resistance.

• Balanced automatically, big gap design on connection of disc and stem, disc is free on the vertical flat against stem, it can balance the tolerance from machining and sealing surface. Good connection without leakage. Achieve functions of both reducing dynamic pressure and reducing static pressure.

• Ductile iron castings with nodularity higher than 90%, foundry in house with advanced melting technology and strict quality control system, testing reports and testing bars can be supplied with order. Records and testing bars maintained for one year in the factory.

• Good corrosion resistance, with stainless steel, copper alloy, rubber made from DuPont and other rust- resisting material, fusion bonded epoxy coating both for interior and exterior surface of the basic valve. All the characteristics in accordance with ANSI/AWWA C550 and other international specifications like WRAS, NSF61.

Notes for installation and debugging

• All the Pressure Reducing Valves have been finished initial debugging tests before delivery. Further dubugging test is also suggested during using according to different working conditions. After the pipe system becomes stable, please loose the adjusting screw on the top of pilot valve to the top- most position.

• After the pipe system becomes stable, please loose the adjusting screw on the top of pilot valve to the top- most position.

• Tighten adjusting screw of pilot valve in clockwise slowly. When outlet pressure increase to the set pressure please fasten the locknut under the adjusting screw.

• If go beyond the set pressure during adjusting, please repeat the above steps. Remember, pressure can be only adjusting from low level to high level and pay attention to make the adjusting slowly.

◔Technical Parameter

Accuracy of Surface Control: ±25mm

Common Problems | Proposed Solutions |

Basic valve does not close when water meets specified level and continue to supply water. | a.Check if any sundries on the sealing surface of basic valve or pilot valve. b.Check if any damage on the sealing surface of basic valve or pilot valve. c.Check if block on lever of controlling angle valve. e.Check if any damage for diaphragm. |

Level adjusting is not accurate and float jumps strongly. | a.Check if the float was installed close to water outlet. If yes, please move it to far away from the water outlet. Or you can use barrel to avoid the affection of the wave. b.Check the location of float and make sure the top-most position which float can catch is the set-level of the water box. |

Reasonable suggestion | To make sure water won't exceed set-level double insurances is recommended. That's to assemble two position two-way solenoid valve before the controlling angle valve to make sure that the valve can be closed in case of emergency. |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved