Gate valves serve to cut the medium flow in the piping system, widely used in the field of potable water, water supply and drainage, sewage disposal, irrigation, air conditioning, fire protection as well as chemical and energy industry.

◔ Material:Ductile Iron EN-GJS-450-10

Body, bonnet, wedge, handwheel and operating nut are all produced in ductile iron material which provides guarantee for high strength and good corrosion resistance.

◔ Triple O-ring Stem Seals

The lower O-ring isolates the stem thrust collar bearing area from the waterway. The upper two O-rings can easily be replaced in the line while the valve is under pressure in the open position.

◔ Stainless Steel Stem, Brass Thrust Collar and Bronze Wedge Nut

This life-tested MEIDE design has repeatedly proven its superior strength and abrasive resistance.

◔ Fusion Bonded Epoxy Coating

Fusion bonded epoxy coating in accordance with ANSI/AWWA C550 for both interior and exterior surface which provides reliable corrosion resistance.

◔ Long Service Life with Resilient Seat Cycling Test 1,000 times

The Valve has been subjected to 1,000 cycles of operation at a maximum rate of 6 cycles of operation per minute from fully closed to fully open and from fully open to fully closed positions under cycled hydrostatic pressure.

• Connection Ends: Flange to BS EN 1092-2:1997

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550

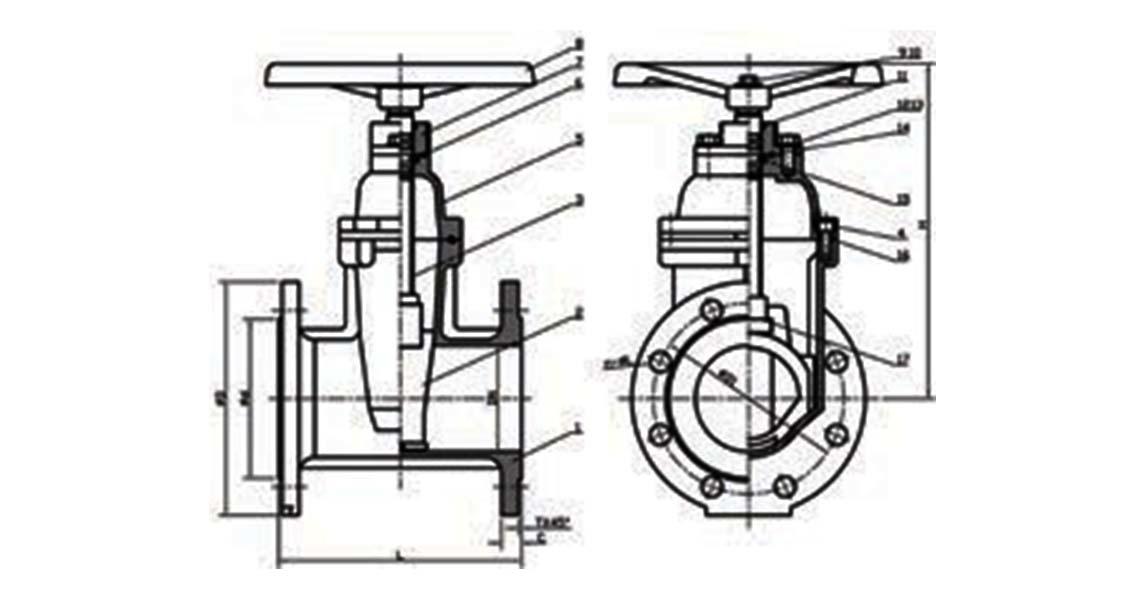

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 |

|

2 | Resilient Wedge Disc | EN-GJS-450-10+EPDM |

|

3 | Stem | SS420 | SS304, SS316, SS431, Al-bronze |

4 | Nut | Carbon Steel Zinc Plated | SS304, SS316 |

5 | Bonnet | EN-GJS-450-10 |

|

6 | O-Ring | NBR | EPDM |

7 | Gland | EN-GJS-450-10 |

|

8 | Handwheel | EN-GJS-450-10 | Pressed Steel |

9 | Bolt | Carbon Steel Zinc Plated | SS304, SS316 |

10 | Flat Washer | Carbon Steel Zinc Plated | SS304, SS316 |

11 | Ring Wiper | NBR | EPDM |

12 | Bolt | Carbon Steel Zinc Plated | SS304, SS316 |

13 | Flat Washer | Carbon Steel Zinc Plated | SS304, SS316 |

14 | O-Ring | NBR | EPDM |

15 | Thrust Washer | Brass HPb59-1 |

|

16 | Bonnet Gasket | EPDM | NBR |

17 | Wedge Nut | Brass HPb59-1 | Bronze ZQSn5-5-5 |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

DN | PN | Dimensions(mm) | ||||||||

Inch | mm | L | H | D | D1 | d | C | T | n-d | |

2" | 50 | 10/16 | 178 | 218 | 165 | 125 | 99 | 19 | 3 | 4-Φ19 |

2.5" | 65 | 10/16 | 190 | 232 | 185 | 145 | 118 | 19 | 3 | 4-Φ19 |

3" | 80 | 10/16 | 203 | 281 | 200 | 160 | 132 | 19 | 3 | 8-Φ19 |

4" | 100 | 10/16 | 229 | 316 | 220 | 180 | 156 | 19 | 3 | 8-Φ19 |

5" | 125 | 10/16 | 254 | 393 | 250 | 210 | 184 | 19 | 3 | 8-Φ19 |

6" | 150 | 10/16 | 267 | 420 | 285 | 240 | 211 | 19 | 3 | 8-Φ23 |

8" | 200 | 10 | 292 | 490 | 340 | 295 | 266 | 20 | 3 | 8-Φ23 |

16 | 12-Φ23 | |||||||||

10" | 250 | 10 | 330 | 626 | 405 | 350 | 319 | 22 | 3 | 12-Φ23 |

16 | 355 | 12-Φ28 | ||||||||

12" | 300 | 10 | 356 | 722 | 460 | 400 | 370 | 24.5 | 4 | 12-Φ23 |

16 | 410 | 12-Φ28 | ||||||||

14" | 350 | 10 | 381 | 800 | 520 | 460 | 428 | 26.5 | 4 | 16-Φ23 |

16 | 470 | 16-Φ28 | ||||||||

16" | 400 | 10 | 406 | 870 | 580 | 515 | 480 | 28 | 4 | 16-Φ28 |

16 | 525 | 16-Φ31 | ||||||||

18" | 450 | 10 | 432 | 1108 | 640 | 565 | 530 | 30 | 4 | 20-Φ28 |

16 | 585 | 548 | 20-Φ31 | |||||||

20" | 500 | 10 | 457 | 1130 | 715 | 620 | 582 | 31.5 | 4 | 20-Φ28 |

16 | 650 | 609 | 20-Φ34 | |||||||

24" | 600 | 10 | 508 | 1311 | 840 | 725 | 682 | 36 | 5 | 20-Φ31 |

16 | 770 | 720 | 20-Φ37 | |||||||

Product Warranty

Within eighteen months of completion inspection or within twelve months of the start of usage , whichever is shortest ,VMV valve will repair or replace products or the faulty components of products free of charge in the event of failure under normal usage attributable to inadequate design or manufacturing on the part of VMV valve.

However, repairs or replacements will be charged in any of the following cases . Also note that if a separate agreement is in effect. That agreement shall take precedence.

(1) When the product has been used in an incorrect manner which deviates from the catalog or instruction manual;

(2) When the product failure is due to careless handing such as jamming with foreign substances or the sticking of excessive water stain;

(3) When the product has been disassembled ,repaired or altered by a third party other than VMV valve;

(4) When the product has been subject to cases beyond the control of VMV valve including natural disaster such as wind or flood damage ,earthquakes and electrical storm ,fire , pollution (special environments ) , salt damage, war or acts of terror;

(5) When a failure is due to any other factor deemed to be the responsibility of VMV valve

Technical Specification

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved