Installed before relief valves, atmospheric valves, hydraulic control valves as well as other equipments, strainers serve to filter out the impurities in the flow medium for protection of valves and equipments in the piping system.

◔ Material

Ductile Iron EN-GJS-450-10

Valve body and cover are produced in ductile iron material which provides guarantee for high strength and good corrosion resistance.

◔ Different Options of Screen Mesh Specification

Different options of screen mesh specification available as per different service conditions.

◔ Stainless Steel Stem, Brass Thrust Collar and Bronze Wedge Nut

This life-tested MEIDE design has repeatedly proven its superior strength and abrasive resistance.

◔ Fusion Bonded Epoxy Coating

Fusion bonded epoxy coating in accordance with ANSI/AWWA C550 for both interior and exterior surface which provides reliable corrosion resistance.

• Connection Ends: Flange to BS EN 1092-2:1997

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃ rubber gasket

-10℃- 350℃ graphite gasket

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550

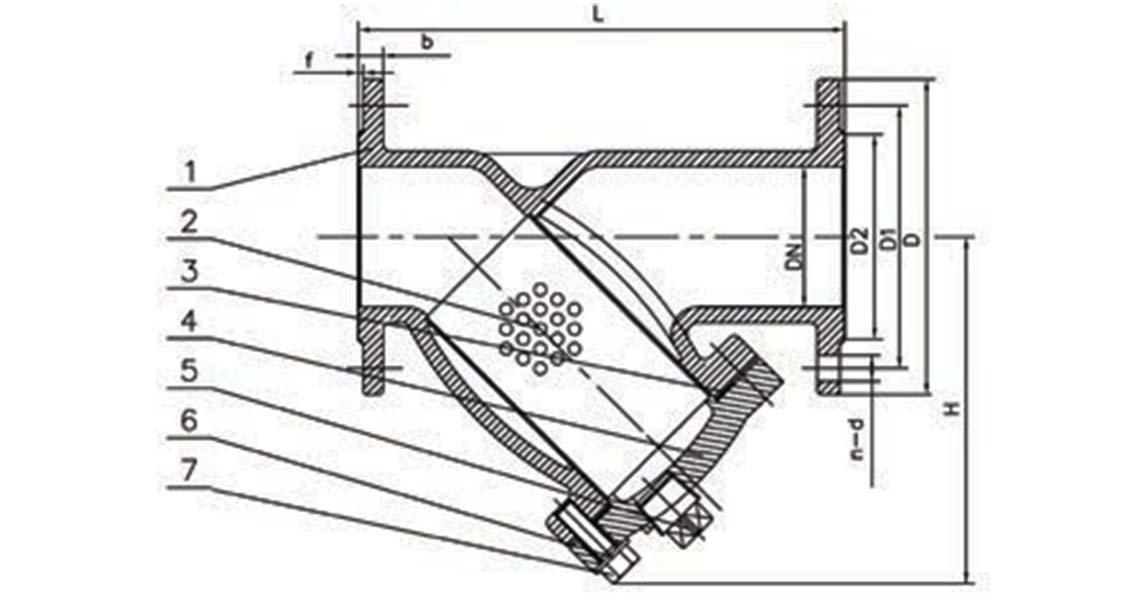

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 |

|

2 | Screen | SS304 (Perforated) | SS304, SS316 (Perforated, Knitted, Double Screen) |

3 | Gasket | EPDM | Graphite+Acanthopore Plate |

4 | Bonnet | EN-GJS-450-10 |

|

5 | Plug | Malleable Iron Galvanized | Bronze ASTM B584 |

6 | Bolt | Carbon Steel Zinc Plated | SS304, SS316 |

7 | Flat Washer | Carbon Steel Zinc Plated | SS304, SS316 |

DN | Sieve No. | Hole Dia. | Free Flow Area(%) | |

Inch | mm |

| mm | % |

2"~2.5" | 50~65 | 25 | 4 | 48 |

3"~4" | 80~100 | 19 | 5 | 59 |

5" | 125 | 14 | 6 | 63 |

6"~12" | 150~300 | 13 | 6.3 | 64 |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

DN | PN | Dimensions(mm) | ||||||||

Inch | mm | L | D | D1 | D2 | b | n-Φd | f | H | |

2" | 50 | 10/16 | 230 | 165 | 125 | 99 | 19 | 4-Φ19 | 3 | 140 |

2.5" | 65 | 10/16 | 290 | 185 | 145 | 118 | 19 | 4-Φ19 | 3 | 175 |

3" | 80 | 10/16 | 310 | 200 | 160 | 132 | 19 | 8-Φ19 | 3 | 198 |

4" | 100 | 10/16 | 350 | 220 | 180 | 156 | 19 | 8-Φ19 | 3 | 229 |

5" | 125 | 10/16 | 400 | 250 | 210 | 184 | 19 | 8-Φ19 | 3 | 287 |

6" | 150 | 10/16 | 480 | 285 | 240 | 211 | 19 | 8-Φ23 | 3 | 304 |

8" | 200 | 10 | 600 | 340 | 295 | 266 | 20 | 8-Φ23 | 3 | 370.5 |

16 | 12-Φ23 | |||||||||

10" | 250 | 10 | 730 | 405 | 350 | 319 | 22 | 12-Φ23 | 3 | 469 |

16 | 355 | 12-Φ28 | ||||||||

12" | 300 | 10 | 850 | 460 | 400 | 370 | 24.5 | 12-Φ23 | 4 | 540 |

16 | 410 | 12-Φ28 | ||||||||

Automatic Membrane Filter Press for Different Mining Powder Filtration

1. this membrane filter press can be used in different concentrate product dewatering

2. high membrane squeezing pressure from PP membrane,better filter cake receiving

3. filtrate and filter cake collecting system for the membrane filter press,cost saving and working efficiency increasing

4. filter press plates consists of membrane filter plates and chamber filter plates

5. big capacity chamber volume avaialbe

6. various working platform for different working conditions

7. full automatic working interface for membrane filter press system,PLC controlling for whole system

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved