Installed before relief valves, atmospheric valves, hydraulic control valves as well as other equipments, strainers serve to filter out the impurities in the flow medium for protection of valves and equipments in the piping system.

◔ Material

Ductile Iron EN-GJS-450-10

Valve body and cover are produced in ductile iron material which provides guarantee for high strength and good corrosion resistance.

◔ Different Options of Screen Mesh Specification

Different options of screen mesh specification available as per different service conditions.

◔ Stainless Steel Stem, Brass Thrust Collar and Bronze Wedge Nut

This life-tested MEIDE design has repeatedly proven its superior strength and abrasive resistance.

◔ Fusion Bonded Epoxy Coating

Fusion bonded epoxy coating in accordance with ANSI/AWWA C550 for both interior and exterior surface which provides reliable corrosion resistance.

• Connection Ends: Groove to ISO 6182

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃ rubber gasket

-10℃- 350℃ graphite gasket

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550 or painting upon request

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 |

|

2 | Screen | SS304 (Perforated) | SS304, SS316 (Perforated, Knitted, Double Screen) |

3 | Gasket | EPDM | Graphite+Acanthopore Plate |

4 | Bonnet | EN-GJS-450-10 |

|

5 | Plug | Malleable Iron Galvanized | Bronze ASTM B584 |

6 | Bolt | Carbon Steel Zinc Plated | SS304, SS316 |

7 | Flat Washer | Carbon Steel Zinc Plated | SS304, SS316 |

DN | Sieve No. | Hole Dia. | Free Flow Area(%) | |

Inch | mm |

| mm | % |

11/2"~6" | 40~150 | 120 | 1.5 | 33 |

8"~12" | 200~300 | 47 | 2 | 23 |

14"~16" | 350~400 | 61 | 2 | 30 |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

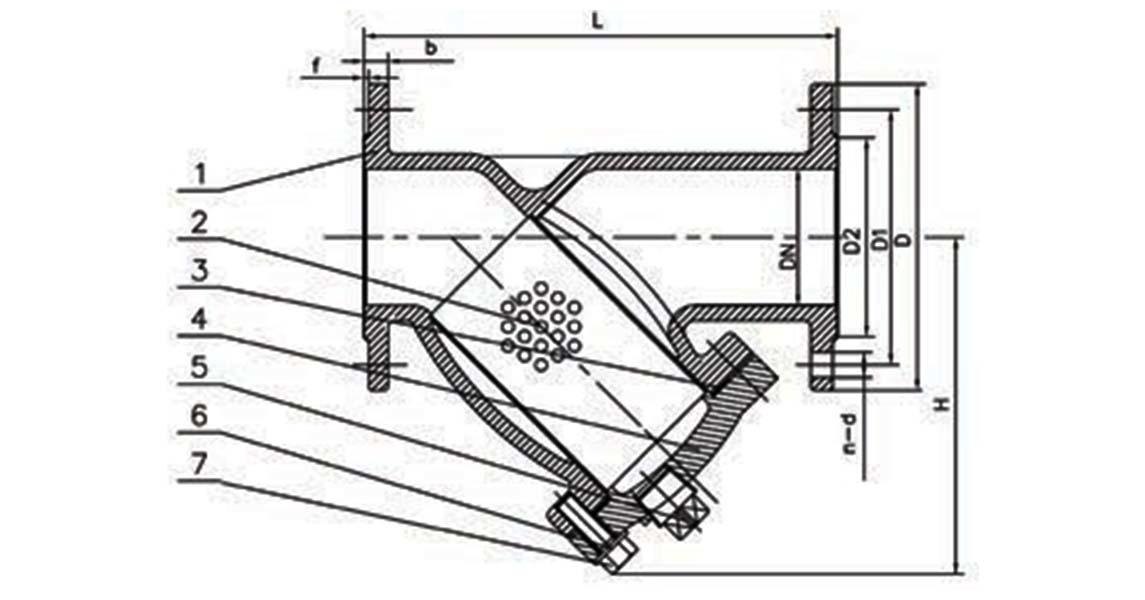

DN | PN | Dimensions(mm) | ||||||||

Inch | mm | L | D | D1 | D2 | b | n-Φd | f | H | |

1/2" | 15 | 10/16 | 130 | 95 | 65 | 45 | 14 | 4-Φ14 | 2 | 59 |

3/4" | 20 | 10/16 | 150 | 105 | 75 | 56 | 16 | 4-Φ14 | 2 | 68 |

1" | 25 | 10/16 | 160 | 115 | 85 | 65 | 16 | 4-Φ14 | 3 | 70 |

11/4" | 32 | 10/16 | 180 | 140 | 100 | 76 | 18 | 4-Φ19 | 3 | 86 |

1.5" | 40 | 10/16 | 200 | 150 | 110 | 90 | 19 | 4-Φ19 | 3 | 140 |

2" | 50 | 10/16 | 230 | 165 | 125 | 99 | 19 | 4-Φ19 | 3 | 140 |

2.5" | 65 | 10/16 | 290 | 185 | 145 | 118 | 19 | 4-Φ19 | 3 | 175 |

3" | 80 | 10/16 | 310 | 200 | 160 | 132 | 19 | 8-Φ19 | 3 | 198 |

4" | 100 | 10/16 | 350 | 220 | 180 | 156 | 19 | 8-Φ19 | 3 | 229 |

5" | 125 | 10/16 | 400 | 250 | 210 | 184 | 19 | 8-Φ19 | 3 | 287 |

6" | 150 | 10/16 | 480 | 285 | 240 | 211 | 19 | 8-Φ23 | 3 | 304 |

8" | 200 | 10 | 600 | 340 | 295 | 266 | 20 | 8-Φ23 | 3 | 370.5 |

16 | 12-Φ23 | |||||||||

10" | 250 | 10 | 730 | 405 | 350 | 319 | 22 | 12-Φ23 | 3 | 469 |

16 | 355 | 12-Φ28 | ||||||||

12" | 300 | 10 | 850 | 460 | 400 | 370 | 24.5 | 12-Φ23 | 4 | 540 |

16 | 410 | 12-Φ28 | ||||||||

14" | 350 | 10 | 838 | 520 | 460 | 429 | 26.5 | 16-Φ23 | 4 | 625 |

16 | 470 | 16-Φ28 | ||||||||

16" | 400 | 10 | 864 | 580 | 515 | 480 | 28 | 16-Φ28 | 4 | 715 |

16 | 525 | 16-Φ31 | ||||||||

DESCRIPTION OF HYDRAULIC FILTER PRESS MACHINE:

High feeding pressure ceramic slurry hydraulic filter press machine is a kind of solids-liquid separator, widely application.

Hydraulic filter press is perfect for stone, kaolin, wastwater, ceramic, buliding materials industry, clay filter press machine special advantage is its high working pressure, and the maximum pressure can reach 2.5MPa, ensure drier filter cake..

FEATURES OF HYDRAULIC FILTER PRESS MACHINE:

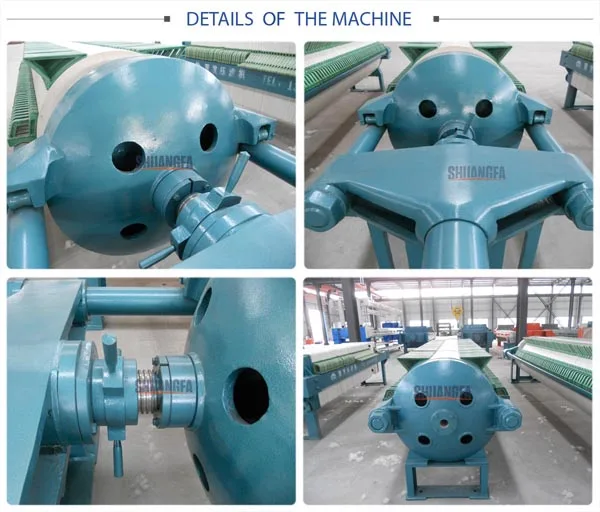

1, After hydraulic filter press machine filtration, the water content of filter cakes is quite low because of its high filtering pressure.

2, Automatic hydraulic maintaining pressure, manual plate shifting, simple and easy operation.

3, Main beam of hydraulic filter press machine is made of high quality carbon steel with sand blasting processing and it is of high intensity and corrosion resisting.

4, The filter plate of hydraulic filter press machine is made of pure reinforced PP, resistes to stronger corrosion and endure high pressure and service longer, and every plates is tested under high pressure 27 MPa.

5, The quantity of hydraulic filter press machine plate can be increased or decreased, then can be used in different liquid.

6, Hydraulic pistons of hydraulic filter press machine are made by steel 45 after surface processing with feature of high hardness, anti-wearing, long life-span.

DETAILS OF HYDRALIC FILTER PRESS MACHINE:

WORKING PRINCIPLE OF HYDRAULIC FILTER PRESS MACHINE:

Filter chambers of hydraulic filter press machine are formed between pressed filter plates when the pressing device drives the pressing plate.

Feeding pump squeezes material through the pore from thrust plate into the filter chambers, solid particles are intercept in the filter chambers forming cake, while liquid was discharged out of the machine through cake and filter cloth.

APPLICATION OF HYDRAULIC FILTER PRESS MACHINE:

High feeding pressure ceramic slurry hydraulic ilter press machine is applicable for clarification and filteration of liquid and can be adopted widely in many industries including chemical industry, metallurgy, pharmacy, food, etc.

The hydraulic filter press machine has the advantages of large filtering area and easy operation and maintenance.

TECHNICAL PARAMETETER OF HYDRAULIC FILTER PRESS MAHCINE:

pls note: these above model is only a part of all models we have, pls contact us for more details!

STANARD PACKING & DELIVERY ON TIME:

OUR SERVICE:

1, Pre-sale services:

We will happily assist you in getting the information you need to make a decision on which products best fit your needs.We want you to feel good about your purchase.

We can design and manufacture products as per your special requirements.If required, we can train your technical personnel for you.

2, Services during the sale:

We strictly adhere to the principle of "the customer first".Your needs and concerns will be addressed to your complete satisfaction.

We can help clients to draft solutions to their specific situations.

3, After-sale services:

Our products are all guaranteed for a full year. During this period, if there is any quality problem, we repair it free of charge.

If there is any problem, we will take measures to solve it immediately,on-site.technical exchanging is also provided for you.

FAQ:

1, What products you provide?

Chamber filter press, membrane filter press, plate and frame filter press, belt filter press,vacuum belt filter, round filter press, cast iron filter press, stainless steel filter machine, filter plate and filter cloth etc.

2, What's your MOQ?

We will indicate the MOQ for each item in the quotation list, generally the MOQ is 1set.

3, What is the payment terms?

TT and L/C are acceptable and TT will be more appreciated.

30% advance payment by T/T, 70% to be paid before delivery of goods by T/T.

4, Do you accept OEM?

Yes, we can manufacture according to your requirement.

5, What is the machine warranty?

All the machines from my factory have 1 year warranty.

6, Is on site installation & commissioning available?

Yes.

7, Can I visit you?

Sure, of course, welcome to visit our factory at any time!

Send Message or Chat Now to Get Details!!!

Tips: please tell me your material and capacity to become our quality clients which will have 2%-10% discount

Please tell me your demand information, so we can send you accurate quotation:

1, What's the raw materials you want to process?

2, What's the total processing capacity you want tons per hour?

3, What's the solid content in the raw material(%)?

4, Your email address or phone number

5, Other requirements.

You can contact me by the following ways also. we will be happy to serve you.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved