Check valves serve to prevent the backflow of medium in the piping system for protection of important equipments, widely used in the field of potable water, water supply and drainage, sewage disposal, irrigation, air conditioning, fire protection as well as chemical and energy industry.

◔ Material:Ductile Iron EN-GJS-450-10

Valve body, bonnet, disc are all produced in ductile iron material which provides guarantee for high strength and good corrosion resistance.

◔ Fusion bonded epoxy coating

Fusion bonded epoxy coating in accordance with ANSI/AWWA C550 for both interior and exterior surface which provides reliable corrosion resistance.

◔ Small hydraulic friction loss with reasonable structure design

• Connection Ends: BS EN 1092 PN10/PN16, AS 2129 TABLE E, JIS B2212 10K, BS 10 TABLE D/E

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550

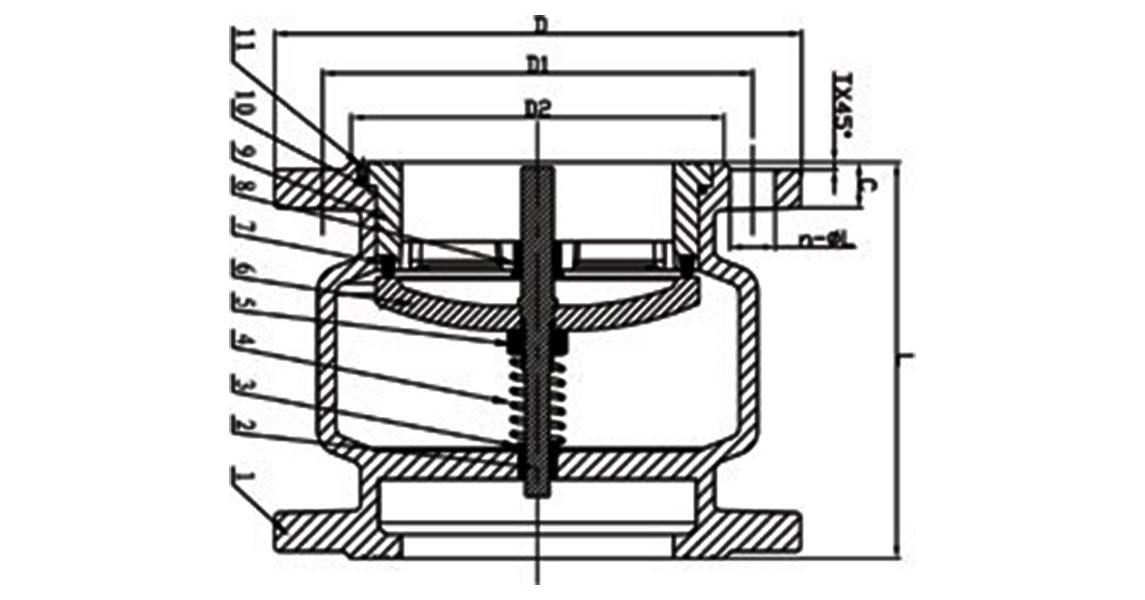

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 |

|

2 | Stem | SS420 | SS304, SS316, SS431 |

3 | Hinge Bushing | Brass Hpb59-1 |

|

4 | Spring | SS304 | SS316 |

5 | Nut | SS304 | SS316 |

6 | Disc | EN-GJS-450-10 |

|

7 | O-Ring | EPDM | NBR |

8 | Hinge bushing | Brass Hpb59-1 |

|

9 | Seat | EN-GJS-450-10 |

|

10 | O-Ring | NBR | EPDM |

11 | Screw | Carbon Steel Zinc Plated | SS304, SS316 |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

DN | Dimensions(mm) | |||||||

Inch | mm | L | D | D1 | D2 | C | T | n-φL |

2" | 50 | 120 | 165 | 125 | 99 | 19 | 3 | 4-Ø19 |

2.5" | 65 | 135 | 185 | 145 | 118 | 19 | 3 | 4-Ø19 |

3" | 80 | 155 | 200 | 160 | 132 | 19 | 3 | 8-Ø19 |

4" | 100 | 165 | 220 | 180 | 156 | 19 | 3 | 8-Ø19 |

5" | 125 | 190 | 250 | 210 | 184 | 19 | 3 | 8-Ø19 |

6" | 150 | 210 | 285 | 240 | 211 | 19 | 3 | 8-Ø23 |

8" | 200 | 260 | 340 | 295 | 266 | 20 | 3 | 12-Ø23 |

10" | 250 | 285 | 405 | 355 | 319 | 22 | 3 | 12-Ø28 |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved