Resilient centerline butterfly valves usually serve to cut off medium flow in the piping system, widely applied in the field of potable water, water supply and drainage, sewage disposal, irrigation, air conditioning, fire protection as well as chemical and energy industry. The design of the butterfly valves, however, makes it also suitable to serve as adjusting valve.

◔ Material

Body and lever are all produced in ductile iron material (EN-GJS-450-10) which provides guarantee for high strength and good corrosion resistance. Different options of the disc and seat, e.g. disc of DI nickel or nylon 11 coated, different series of stainless steel, Al-bronze, seat in EPDM, NBR or Fluororubber, makes it suitable to be applied under different working conditions.

◔ Design

Universal flange connection to BS EN 1092 PN6/10/16, ASME B16.1 CL 125, ASME B16.5 CL 150, GB9113, JIS B2112 10K, AS 2129 Table E, BS 10 Table D/E.

Different options of operation including lever handle, gear box, gear box with tamper switch, electric drive, and pneumatic drive, etc.

Different options of rubber seat including insert rubber seat, rubber vulcanized on valve body and boot rubber seat.

◔ Coating

Fusion bonded epoxy coating of valve body and lever provides reliable corrosion resistance.To achieve higher corrosion resistance, factory is also able to supply Nylon 11 coated disc. Nylon 11 coating is thermoplastic plant coating approved by USDA with high corrosion resistance and antisepsis which can be applied where there is strict requirement for anti- corrosion.

• Design Standard: BS EN 593

• Connection Ends: BS EN 1092 PN10/PN16, AS 2129 TABLE E, JIS B2212 10K, BS 10 TABLE D/E

• Top Flange Standard: ISO 5211

Stem drive by keys, parallel or diagonal square or flat head

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550

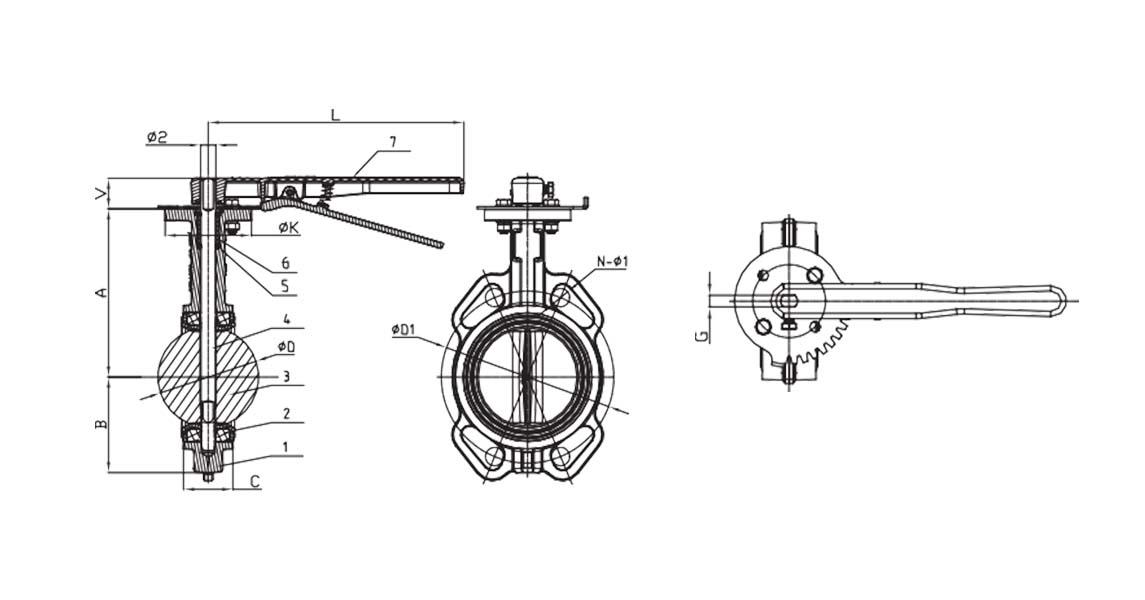

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 |

|

2 |

Seat | DN40~400: EPDM & Backing | NBR/Fluororubber&Backing EPDM/NBR Vulcanized on Valve Body Soft Seat in EPDM/NBR |

3 | Disc | EN-GJS-450-10 | SS304, SS316, AL-Bronze C95400 |

4 | Stem | DN50~350: SS420, One-Piece Stem Design DN400~750: SS431, Two-Piece Stem Design | SS304, SS316, SS416, SS431 |

5 | O-Ring | NBR | EPDM |

6 | Bushing | DN40~350: Nylon 1010 | PTFE |

7 | Lever | EN-GJS-450-10 | Aluminum |

8 | Shaft Cover (DN400~750) | EN-GJS-450-10 |

|

9 | Gear Box | Cast Iron EN-GJL-200 | EN-GJS-450-10 |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

DN | Dimensions(mm) | |||||||||||||||||

Inch | mm | A | B | V | C | ØD | Ø2 | ØK | G | L | ØD1 | N-Ø1 | ISO 5211 | Ø3 | H | H1 | H2 | P |

1.5" | 40 | 138 | 64.5 | 32 | 33 | 43.9 | 14 | 90 | 9.45 | 267 | 110 | 4-Ø19 | F07 | 150 | 206 | 158 | 52 | 43.5 |

2" | 50 | 140.5 | 64.5 | 32 | 43 | 53.9 | 14 | 90 | 9.53 | 267 | 125 | 4-Ø19 | F07 | 150 | 206 | 158 | 52 | 43.5 |

2.5" | 65 | 153 | 72 | 32 | 46 | 65.2 | 14 | 90 | 9.53 | 267 | 145 | 4-Ø19 | F07 | 150 | 206 | 158 | 52 | 43.5 |

3" | 80 | 157.5 | 86 | 32 | 46 | 79.7 | 14 | 90 | 9.53 | 267 | 160 | 8-Ø19 | F07 | 150 | 206 | 158 | 52 | 43.5 |

4" | 100 | 176 | 100 | 32 | 52 | 105 | 16 | 90 | 11.14 | 267 | 180 | 8-Ø19 | F07 | 150 | 206 | 158 | 52 | 43.5 |

5" | 125 | 191 | 112 | 32 | 56 | 130 | 16 | 90 | 11.14 | 267 | 210 | 8-Ø19 | F07 | 150 | 206 | 158 | 52 | 43.5 |

6" | 150 | 202.5 | 128 | 32 | 56 | 156 | 20 | 90 | 12.7 | 267 | 240 | 8-Ø23 | F07 | 150 | 206 | 158 | 52 | 43.5 |

8" | 200 | 243.5 | 162 | 45 | 60 | 206.7 | 26 | 125 | 20.6 | 356 | 295 | 12-Ø23 | F10 | 300 | 310 | 239 | 69 | 62.5 |

10" | 250 | 273 | 194 | 45 | 68 | 253.3 | 26 | 125 | 20.6 | 490 | 355 | 12-Ø28 | F10 | 300 | 310 | 239 | 69 | 62.5 |

12" | 300 | 311 | 223 | 45 | 78 | 301.9 | 28 | 125 | 22.1 | 490 | 410 | 12-Ø28 | F10 | 300 | 307 | 229 | 73 | 77.5 |

14" | 350 | 340 | 267 | 48 | 78 | 333.9 | 31.6 | 150 | 22.1 | - | 470 | 16-Ø28 | F12 | 300 | 307 | 229 | 73 | 77.5 |

16" | 400 | 400 | 319.5 | 48 | 102 | 389.6 | 33.2 | 175 | 27 | - | 525 | 16-Ø31 | F14 | 380 | 418 | 288 | 110 | 120 |

18" | 450 | 422 | 345.4 | 48 | 114 | 441 | 38.1 | 175 | 27 | - | 585 | 20-Ø31 | F14 | 380 | 418 | 288 | 110 | 120 |

20" | 500 | 480 | 380 | 70.2 | 127 | 492.4 | 41.2 | 210 | - | - | 650 | 20-Ø34 | F16 | 380 | 465 | 215 | 123 | 185 |

24" | 600 | 562 | 441 | 70.2 | 154 | 592.8 | 50.6 | 210 | - | - | 770 | 20-Ø37 | F16 | 380 | 500 | 215 | 129 | 185 |

Inch | mm | A | B | V | C | ØD | Ø2 | ØK | G | L | ØD1 | N-Ø1 | ISO 5211 | Ø3 | H | H1 | H2 | P |

|

|

|

|

|

|

|

|

|

|

| PN10 |

|

|

|

|

|

| |

28" | 700 | 575 | 505 | 70.2 | 165 | 695 | 63.4 | 300 | - | - | 840 | 24-Ø31 | F25 | 380 | 543 | 213 | 132 | 218 |

30" | 750 | 660 | 550 | 70.2 | 165 | 744 | 63.4 | 300 | - | - | - | - | F25 | 380 | 543 | 213 | 132 | 218 |

Welcome to SYI Group

double flanged concentric butterfly valve - SYI GROUP

About Our double flanged concentric butterfly valve- SYI GROUP :

About Our double flanged concentric butterfly valve- SYI GROUP :

Technical Specifications:

Design: EN593

Face to face: EN558-1

Flange drilling: EN1092

Upper flange connection: ISO 5211

Main Parts and Material:

| Item | Part Name | Material | Item | Part Name | Material |

| 1 | Body | CI+NBR/EPDM or DI+NBR/EPDM | 3 | Body | CI+NBR/EPDM or DI+NBR/EPDM |

| 2 | O-ring | Rubber | 4 | O-ring | Rubber |

Main Dimensions:

| DN(MM) | A | B | D | L1 |

| 50 | 83 | 120 | 165 | 111 |

| 65 | 93 | 130 | 185 | 115 |

| 80 | 100 | 145 | 200 | 117 |

| 100 | 114 | 155 | 220 | 130 |

| 125 | 125 | 170 | 250 | 143 |

| 150 | 143 | 190 | 285 | 143 |

About SYI Group Information :

About SYI Group Information :

Specialist in Municipal, Drainage & Machinery Products & Services

SYI is GroupGroup Companies have served the society for over 20 years with best Municipal, Drainage and Machinery products.

···SYI Foundry

···SYI Pipeline Corporation

···SYI Industrial Casting Division

···SYI Forging Factory

···SYI Aluminum Division

SYI is the Specialist in Municipal, Drainage & Machinery Products & Services, including pipes, fititngs,couplings, valves, manhole covers, bollards, and OEM products in different materials ,sizes and technical processes. Now I invite you to visit our site www.syigroup.com.

Our aim is to provide all of our customers with VALUE of the products in stead of only low prices!

About SYI Valves :

About SYI Valves :

Gate Valve | Butterfly Valve | Y-Strainer Valve |

| ||

Underground Fire Hydrant | Cast Steel Gate Valve | Cast Steel Globe Valve |

| ||

Cast Steel Swing Check Valve | Russian Standard Gate Valve | Swing Check Valve |

| ||

double flanged concentric butterfly valve- SYI GROUP

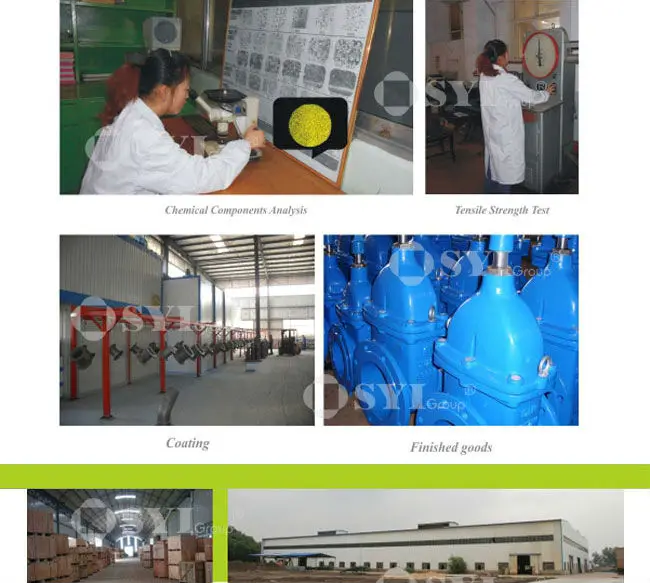

Production Facility :

Production Facility :

" SYI regards quality as an essential and integral part of our business success. To meet this, we have achieved all types of world-known certificates. Manufacturing "SYI" Brand products has evolved as a mark of quality and our products find warmacceptance in domestic as well as international market. "

double flanged concentric butterfly valve - SYI GROUP

Design :

Design :

double flanged concentric butterfly valve - SYI GROUP

We Are Certified !

We Are Certified !

More certification ... (Contact us!)

Contact SYI Group :

Contact SYI Group :

SYI Industrial Co., Ltd.

1. Email: wang#syipipeline.com ( # = @ )

2. Tel: 0086 351 4182605

3. Fax: 0086 351 4040962

4.Website: www.syipipeline.com

You will get our quick reply!

-------------------------------------------------------------------

Best regards

SYI Group

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved