Company Advantages1. A lot of tests for Mech Valve y strainer valve will be carried out. The tests include dimension accuracy, material safety, colorfastness, wearing resistance, moisture-wicking, load-bearing capacity, etc.

2. This product has the desired safety. The clean-cut and rounded edges are the strong guarantees of high levels of safety and security.

3. The product is not easy to deform. The materials adopted feature high rigidity and strength to withstand heavy bodyweight and pressure.

4. Shenzhen Mech Valve Trading Co., Ltd. has the competitive advantage of continuous innovation.

Installed before relief valves, atmospheric valves, hydraulic control valves as well as other equipments, strainers serve to filter out the impurities in the flow medium for protection of valves and equipments in the piping system.

◔ Material

Ductile Iron EN-GJS-450-10

Valve body and cover are produced in ductile iron material which provides guarantee for high strength and good corrosion resistance.

◔ Different Options of Screen Mesh Specification

Different options of screen mesh specification available as per different service conditions.

◔ Stainless Steel Stem, Brass Thrust Collar and Bronze Wedge Nut

This life-tested MEIDE design has repeatedly proven its superior strength and abrasive resistance.

◔ Fusion Bonded Epoxy Coating

Fusion bonded epoxy coating in accordance with ANSI/AWWA C550 for both interior and exterior surface which provides reliable corrosion resistance.

MATERIAL SPECIFICATION

• Connection Ends: Groove to ISO 6182

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550 or painting upon request

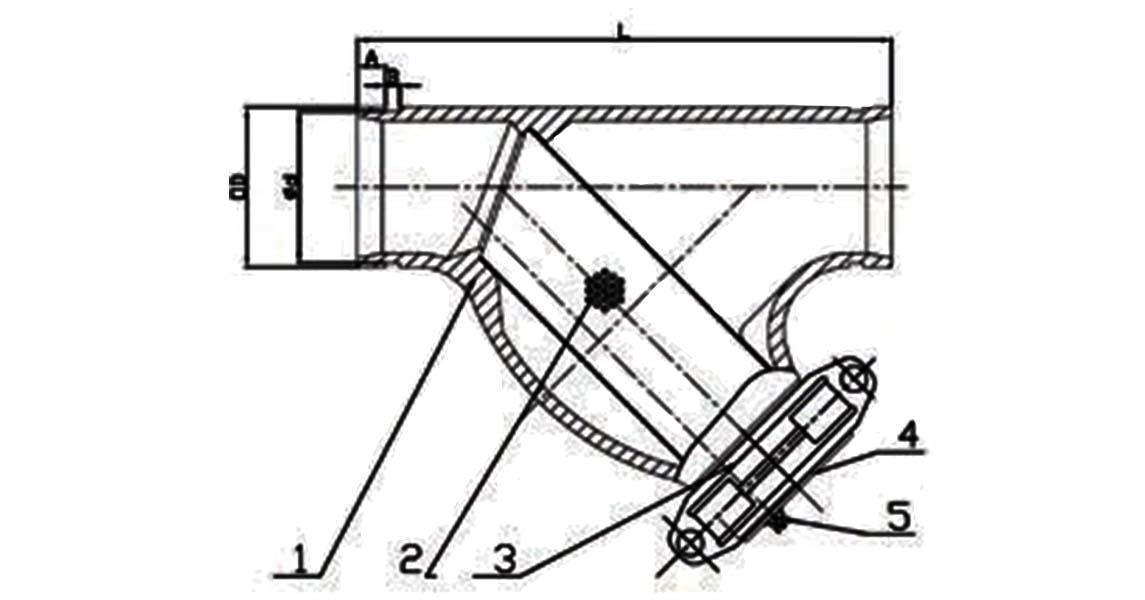

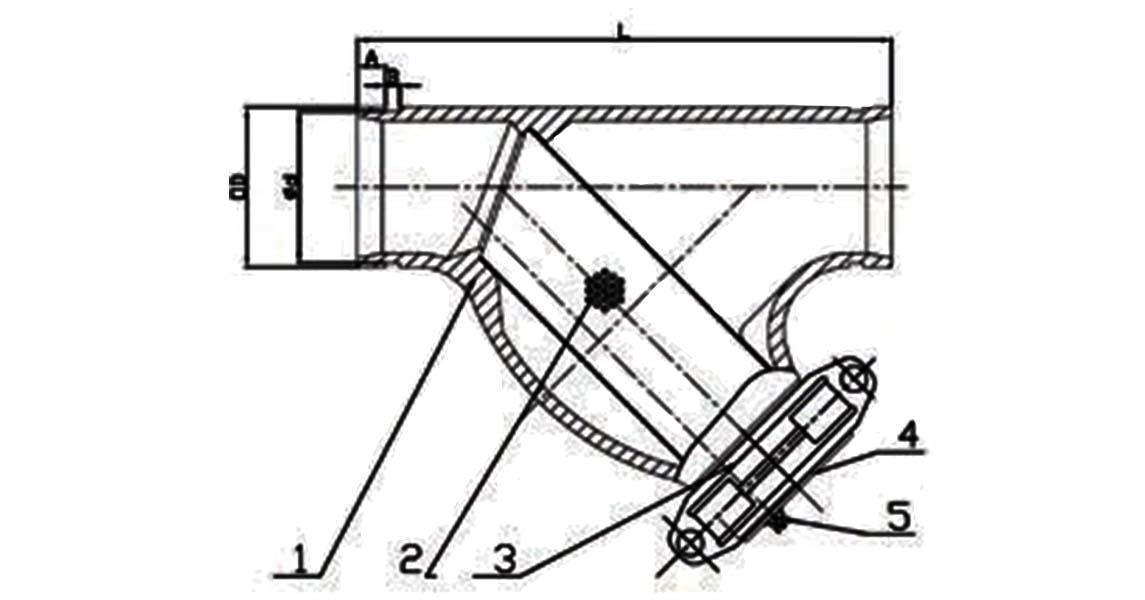

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 | |

2 | Screen | SS304 | SS316 |

3 | Rigid Coupling | EN-GJS-450-10 | |

4 | Cap | EN-GJS-450-10 |

|

STANDARD SCREEN

DN | Sieve No. | Hole Dia. | Free Flow Area(%) |

Inch | mm | | mm | % |

2"~2.5" | 50~65 | 25 | 4 | 48 |

3"~4" | 80~100 | 19 | 5 | 59 |

5" | 125 | 14 | 6 | 63 |

6"~12" | 150~300 | 13 | 6.3 | 64 |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

DN | Dimensions(mm) |

Inch | mm | L | OD | d | A | B |

2" | 50 | 247.5 | 60.3 | 57.15 | 15.88 | 7.92 |

2.5" | 65 | 273 | 73 | 69.09 | 15.88 | 7.92 |

2.5" | 65 | 273.0 | 76.1 | 72.26 | 15.88 | 7.92 |

3" | 80 | 298.5 | 88.9 | 84.94 | 15.88 | 7.92 |

4" | 100 | 362.0 | 114.3 | 110.08 | 15.88 | 9.52 |

5" | 125 | 419.0 | 139.7 | 135.48 | 15.88 | 9.52 |

5" | 125 | 419 | 141.3 | 137.03 | 15.88 | 9.52 |

6" | 150 | 470.0 | 165.1 | 160.90 | 15.88 | 9.52 |

6" | 150 | 470.0 | 168.3 | 163.96 | 15.88 | 9.52 |

8" | 200 | 609.5 | 219.1 | 214.40 | 19.05 | 11.13 |

10" | 250 | 686.0 | 273.0 | 268.28 | 19.05 | 12.70 |

12" | 300 | 762.0 | 323.9 | 318.29 | 19.05 | 12.70 |

Shenzhen Mech Valve Trading Co., Ltd. is a distinguished supplier of quality y strainer valve after years of experience. The company still works hard to improving its brand influence worldwide.

2. Our production capacity occupies steadily in the forefront of the y filter industry.

3. We focus on long-term business partnerships with a small number of top-performing suppliers. We expect our suppliers to deliver products that meet our minimum requirements and to be willing to continuously work with us towards improvements. We offer a culture of empowerment. All of our employees are challenged to be creative, to take risks and to constantly find better ways to do things, so that we can continue to delight our customers and grow our business. We are aware that our business must be conducted in a way that's environmentally sustainable. We will increase the utilization of recycled materials in products to make our products to become 100% circular and renewable. In our company, we aim for a sustainable future. We take responsibility for the safety and health of our employees, customers, and the protection of the environment.

| The filter press is widely used in mining, food, pharmaceutical, petroleum, textile, printing and dyeing, paper making, sewage treatment, etc solid-liquid separation industries. Detailed as: ceramic, glaze waste water, gelatin, edible oil, vinegar, chemicals, food processing, pharmaceuticals, leather tanneries, sewage treatment plants, sugar, fertilizers,petro chemicals. Many oil plants, such as rapeseed, cotton seeds, soybean, shelled peanut, flax seeds, sunflower seeds and palm kernel, etc. Medium and small oil refinery, oil mill and private oil squeezing workshop. Any needs about solid liquid separation, contact Apple freely. |