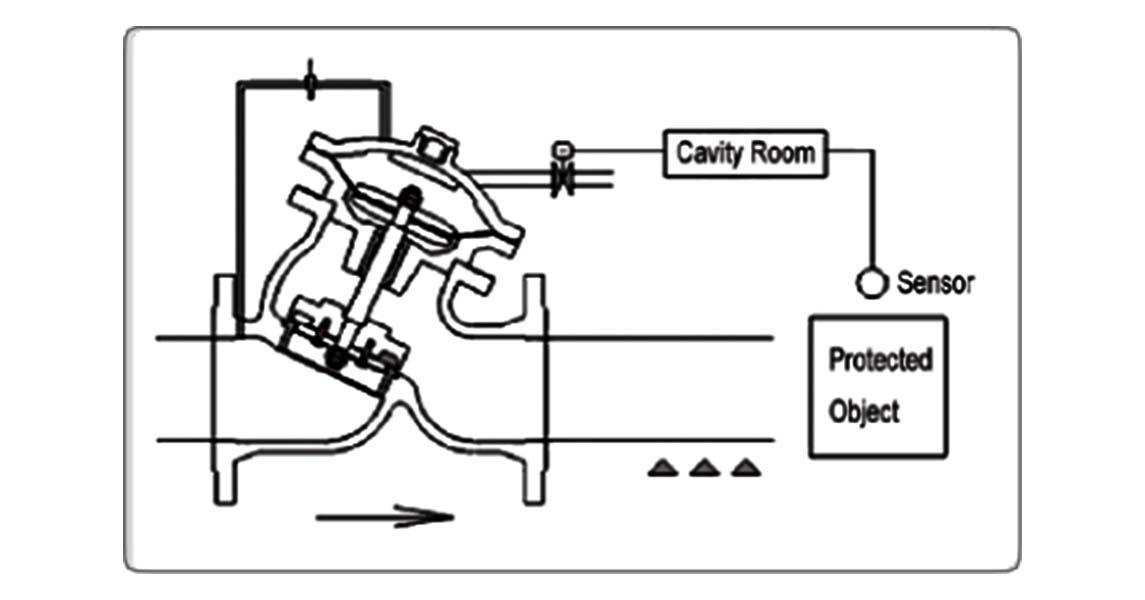

SK790X Deluge Alarm Valve is a diaphragm type of hydraulic control valve driven by the hydraulic pressure within the piping system, functioning as flow control and alarming device in the sprinkler and pre-action system, i.e. to start the sprinkler system for quenching of the fire and send out fire alarm through the fire bell when there is fire detected.

◔Operational principle

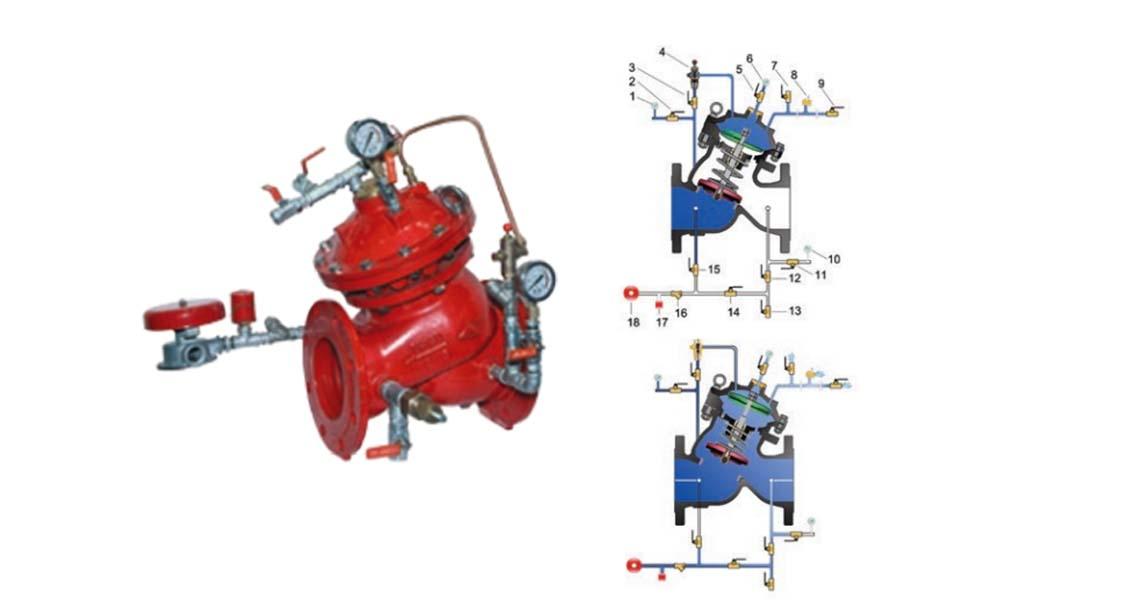

SK790X Deluge Alarm Valve is equipped with solenoid, anti-reset controller, mini strainer, ball valve and pressure gauge, etc..

For deluge valve there is set condition and work condition. When the valve is under set condition, ball valve (3) is open, ball valve (7), solenoid (8) and remote ball valve (9) are closed, the anti-reset controller is connected, and pressure gauge (1) and pressure gauge (6) shows the same value. When ball valve (11) is open, pressure gauge (10) shows 0. When ball valve (12) and (14) are open, (13) & (15) closed, there is no hydraulic pressure for pressure switch (17) , and alarm (18) does not work. Under set condition, you can operate as following if you want to test the pressure switch alarm device (17) and water motor alarm (18): close ball valve (14) and open (15), and then close (15) and open (14) after testing.

In case there is fire detected, the following 3 methods will set the deluge valve into work condition immediately, A: Opening solenoid valve (8) B: Opening ball valve (7) C: Opening remote ball valve (9). Any of the above 3 methods can get the pressure within the control room of the basic valve released rapidly to open the valve and set it into working condition. At this time the sealing ball of anti-reset controller makes controller in a shutdown state, water will pass through the main valve, ball valve (12), (4), pressure switch (17), fire bell (18), the pressure switch bell sends out signal alarms. After fire fighting, close ball valve (7), solenoid valve (8), remote valve (9), press the anti-reset controller handle till the pressure gauge (6) and pressure gauge (1) shows the same value. The deluge alarm valves returns to set condition.Ball valve (2), (5) & (11) are normally open unless need to change the pressure gauge.

◔ Property and advantages

• Driven by pressure of pipe system, work automatically with energy of pipe system to achieve energy conservation and environment protection.

• Controlled by the pilot valve, lower energy consumption, achieve accurate pressure reducing results, have function of stabilizing pressure after the valve.

• Dual cavity design, with functions of fully opening and fully closing. Slow shut causes no pressure fluctuation, and the diaphragm with support is well protected.

• Have internal orifice, connect bottom cavity and outlet of the basic valve, make sure stability of reaction to keep stability of pressure after the valve, avoid any vibration and noise.

• Channel with straight-flow, slight friction loss, no eddy flow and turbulent flow, cut down the damage of cavitation.

• Long pitch orientation design for stem move, stable and no gap resistance.

• Balanced automatically, big gap design on connection of disc and stem, disc is free on the vertical flat against stem, it can balance the tolerance from machining and sealing surface. Good connection without leakage. Achieve functions of both reducing dynamic pressure and reducing static pressure.

• Ductile iron castings with nodularity higher than 90%, foundry in house with advanced melting technology and strict quality control system, testing reports and testing bars can be supplied with order. Records and testing bars maintained for one year in the factory.

• Good corrosion resistance, with stainless steel, copper alloy, rubber made from DuPont and other rust- resisting material, fusion bonded epoxy coating both for interior and exterior surface of the basic valve. All the characteristics in accordance with ANSI/AWWA C550 and other international specifications like WRAS, NSF61.

Notes for installation and debugging

• Please check if pressure switch and alarm bell are in good condition before installation. Make sure water can not leak to system from water supplying system or there's equipment to discharge the leaked water.

Please adjust all the ball valves to make sure the basic valve be in set condition.

• Make sure anti-reset controller is in good condition and seal well before installation. If there's water with pressure in front of the valve, please closed ball valve (7), (9) and electromagnetic valve when it's in empty state behind the basic valve, press the anti-reset controller, when up cavity of basic valve is full of water please check if there's any leakage behind the valve. If no leakage, it said anti-reset controller is in good condition.

Common Problems | Proposed Solutions |

Press anti-reset controller after fire-out, there's still water coming out behind the valve. |

a.Check if any sundries or damage on the sealing surface of basic valve or anti-reset controller. b.Check if any damage on diaphragm. |

When open controlling valve (7), (8) and (9) no water comes out from the basic valve. |

a.Check if controlling valve (7), (8) and (9) were opened. Close them or replace with new ones. b.Check if there's block on stem of basic valve, repair it. |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved