Check valves serve to prevent the backflow of medium in the piping system for protection of important equipments, widely used in the field of potable water, water supply and drainage, sewage disposal, irrigation, air conditioning, fire protection as well as chemical and energy industry.

◔ Material:Ductile Iron EN-GJS-450-10

Valve body, bonnet, disc are all produced in ductile iron material which provides guarantee for high strength and good corrosion resistance.

◔ Fusion bonded epoxy coating

Fusion bonded epoxy coating in accordance with ANSI/AWWA C550 for both interior and exterior surface which provides reliable corrosion resistance.

◔ Small hydraulic friction loss with reasonable structure design

• Connection Ends: BS EN 1092 PN10/PN16, AS 2129 TABLE E, JIS B2212 10K, BS 10 TABLE D/E

• Working Pressure: PN10/PN16

• Temperature Range: 0℃- 80℃

• Coating: Fusion Bonded Epoxy Coating in accordance with ANSI/AWWA C550

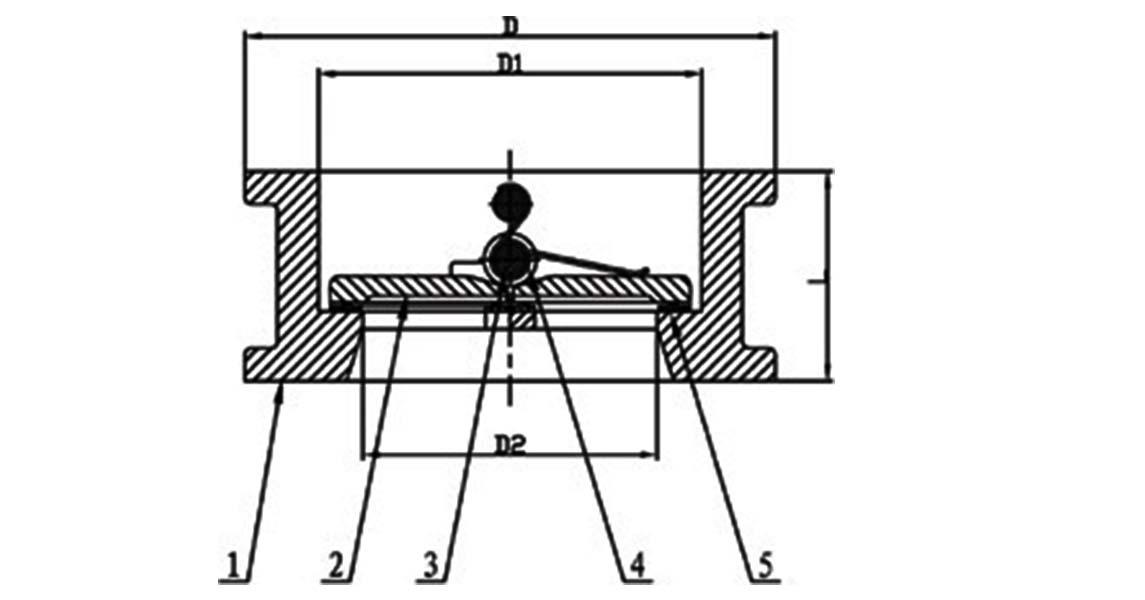

Part No. | Part | Standard Specification | Options |

1 | Valve Body | EN-GJS-450-10 |

|

2 | Disc | EN-GJS-450-10 | SS304, SS316, AL-Bronze UNC 95400 |

3 | Stem | SS420 | SS304, SS316, SS416 |

4 | Spring | SS304 | SS316 |

5 | Rubber Seat |

| NBR |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

DN | PN | Dimensions(mm) | ||||

Inch | mm |

| L | D | D1 | D2 |

2" | 50 | 10/16 | 54 | 107 | 64 | 46 |

2.5" | 65 | 10/16 | 54 | 127 | 78 | 60 |

3" | 80 | 10/16 | 57 | 142 | 94 | 70 |

4" | 100 | 10/16 | 64 | 162 | 117 | 84 |

5" | 125 | 10/16 | 70 | 192 | 145 | 115 |

6" | 150 | 10/16 | 76 | 218 | 170 | 134 |

8" | 200 | 10/16 | 95 | 273 | 224 | 184 |

10" | 250 | 10/16 | 108 | 328 | 265 | 220 |

12" | 300 | 10/16 | 143 | 378 | 310 | 260 |

14" | 350 | 10/16 | 184 | 438 | 360 | 302 |

16" | 400 | 10/16 | 191 | 489 | 410 | 350 |

1.Q:Why do we need to choose your company as our supplier?

1)Product consistency is good, high quality and best service can save your time and money.

2) Quality warranty and on time delivery.

3) Prompt response .

4) I hope we can long-term cooperation,achieve win-win stuation.

2.Q: How many is our minimum order quantity?

A: MOQ is 1 Piece.

3.Q: What's your delivery date?

A: It depends on the quantity. Delivery date is 7-30 days.

4.Q:How many years have you done valves,fittings?

A: More than 13 years.

5.What measures you can provide to ensure our our deal?

A: We are the trade assurance supplier on Alibaba.com. If you place an trade assurance order, you will receive 100% refund of the trade assurance amount for order not meeting agreed

delivery or quality terms.

Purpose:

Freezing weather precaution.

Subsequent to test piping system, valves should be left in opened position for completing drainage product specifications in this catalogues are provided for reference only. For precise measurements, please contact Aquafitting Service.

Main technical parameters:

Basic Design: BS5163

Face to Face: BS5163

Flanges: BS 4504 PN16

Testing: BS 6755

Working Pressure: PN10/16

CONTACT DETAILES:

WEB:www.aquafitting.com

EMAIL: sales1 "at"aquafititing.com

TEL: 86 41182710530

Name: Tina

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved